Dental

Process-safe filling of highly viscous materials

Our dosing technology enables the process-safe filling of highly viscous material such as dental ceramics, tooth whitening gels and polymers for dental products. And it is equally suitable for abrasive products such as polishing pastes.

Process-reliable dosing with a deviation of ±1 % for fill quantities from 0.1 ml is guaranteed by absolute linearity between rotor speed and dosed quantity. Controlled thread breakage thanks to adjustable suck-back at the end of dosing prevents dripping or thread pulling of the different materials.

Application examples from the dental industry

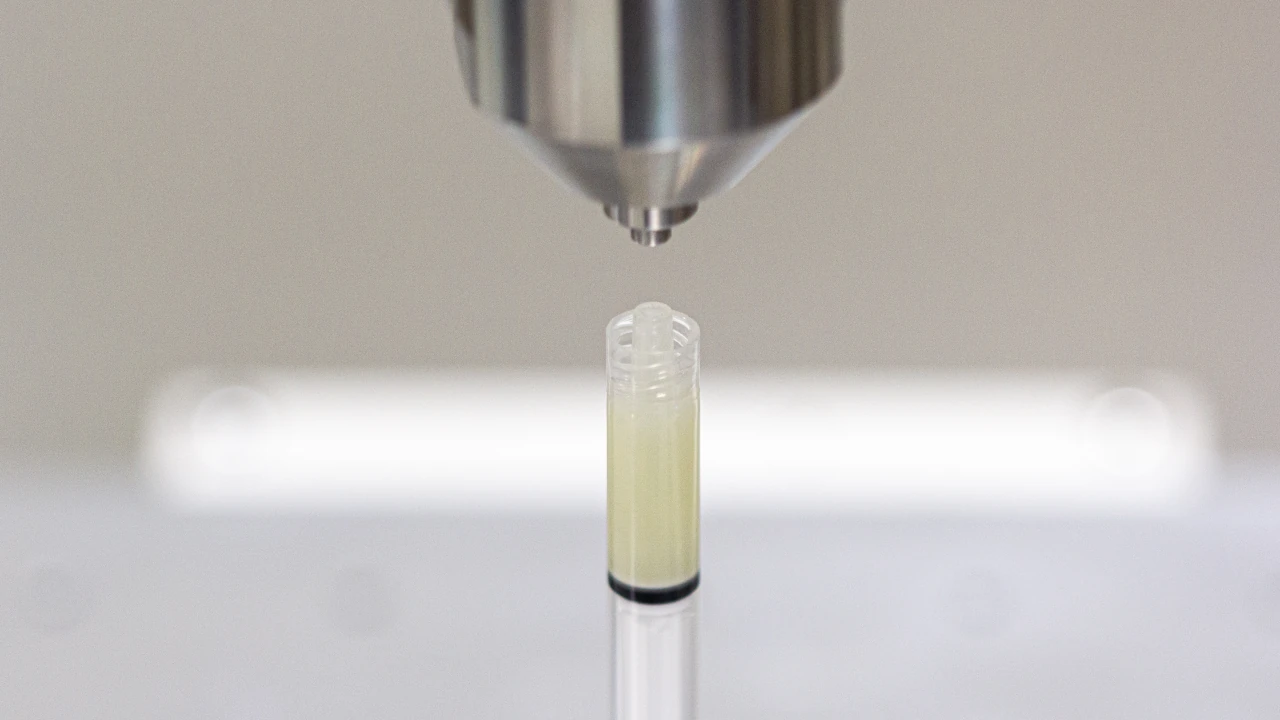

Simple filling of dental syringes – Semi-automatic solution

In the dental industry, many consumables are filled in disposable syringes with a Luer lock attachment. Often manually and therefore very time-consuming. We have a solution to make your production processes more efficient and economical. Not only time savings and safe handling or easy operation are important plus points of our dosing solution. The dosing syringes are filled precisely and gently. Smallest quantities are our specialty. Even at 0.1 ml, we achieve a repeatability and dosing accuracy of >99 %. And this is regardless of the viscosity of your materials. The syringes can be filled via the Luer-Lock attachment as well as via the plunger side. Depending on the application requirement.

Read more about our semi-automatic solution and the advantages it offers for your production here.

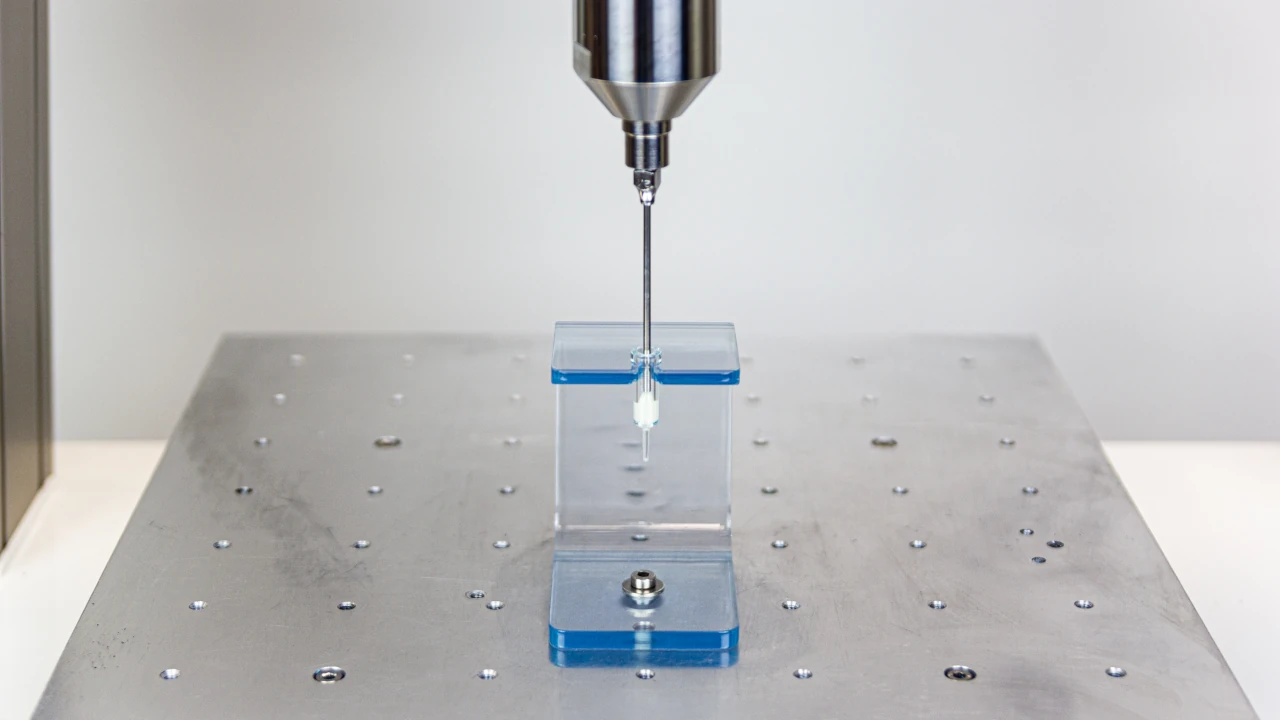

Simple filling of dental syringes – Semi-automatic solution

When filling flowable composites, i.e. filling materials made of plastic and glass, our Hygienic Dispensers are convincing in several ways: with exact dosing quantities and a repeat accuracy of >99 %. In addition, there is no contamination of the packaging or the dosing needle. This reduces material waste and therefore costs. And our technology is particularly suitable for highly abrasive materials; handling is absolutely gentle.

Your advantages at a glance:

- Smallest quantities are filled with high precision

- Perfectly suited for abrasive and difficult dosing materials

- Clean thread break-off thanks to suck-back effect for repeatable dosing results

- Semi- and fully automatic solution

Read here how you can save time and material with our semi- and fully automatic systems. For example, when filling composites.